What are the classifications of high-pressure rubber hoses?

High-pressure oil pipes are mainly classified into high-pressure steel wire braided oil pipes and high-pressure steel wire wound oil pipes according to their manufacturing processes.

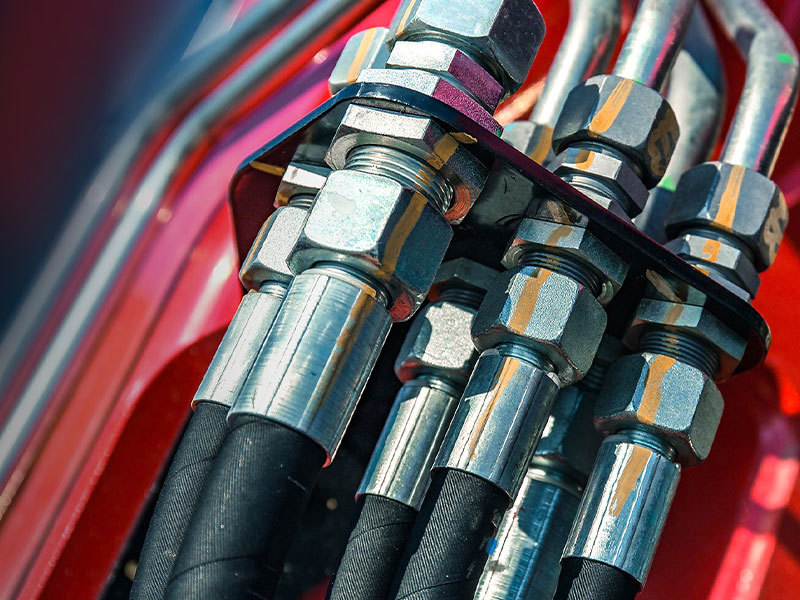

Steel wire wound rubber hose

The structure of high-pressure steel wire wound rubber hoses mainly consists of an inner rubber layer, a middle rubber layer, four or more alternately wound steel wire reinforcing layers, and an outer rubber layer.

The inner rubber layer has the function of subjecting the conveyed medium to pressure and protecting the steel wire from erosion. The outer rubber layer protects the steel wire from damage. The steel wire (ф0.3-2.0 reinforcing layer) layer serves as the skeleton material and plays a reinforcing role.

High-pressure steel wire wound oil pipe (high-pressure oil pipe) application: High-pressure steel wire reinforced hydraulic oil tubes are mainly used in mine hydraulic supports and oilfield development. It is suitable for conveying petroleum-based liquids (such as mineral oil, soluble oil, hydraulic oil, fuel oil, lubricating oil) and water-based liquids (such as emulsions, oil-water emulsions, water) with certain pressure (high pressure) and temperature in the hydraulic systems of mechanization and automation in engineering construction, lifting and transportation, metallurgical forging and pressing, mining equipment, ships, injection molding machinery, agricultural machinery, various machine tools and various industrial sectors It is driven by liquids and can withstand working pressure up to 70-120 mpa.

The working temperature of high-pressure steel wire wound oil pipe (high-pressure oil pipe) is -40℃ to 120℃

Product specification range: DN6mm to DN305mm.

Type: 4SP type - Medium-pressure rubber hose wound with four layers of steel wire.

4SH type - High-pressure rubber hose wound with four layers of steel wire.

R12 type - Four-layer steel wire wound high-temperature and medium-pressure oil pipe for harsh conditions.

R13 type - Multi-layer steel wire wound high-temperature and high-pressure oil pipe for harsh conditions.

R15 type - Multi-layer steel wire wound high-temperature and ultra-high-pressure oil pipe for harsh conditions. [1]

Steel wire braided rubber hose

The structure of high-pressure steel wire braided rubber hoses mainly consists of a liquid-resistant synthetic rubber inner rubber layer, a middle rubber layer, I, II and III steel wire braided layers, and a weather-resistant synthetic rubber outer rubber layer.

However, according to the design principle of high-pressure rubber hoses, the third-layer braided rubber hose plays no role when the hose is under pressure, wasting materials in vain, increasing the weight of the hose itself, and reducing the flexibility of the hose. Therefore, there are no standards for this type of rubber hose in the standards of various countries. Some senior engineers in enterprises still follow the old standards of the past, so there are still people choosing this model when designing.

Applications of high-pressure steel wire braided rubber hoses: High-pressure steel wire reinforced hydraulic oil tubes are mainly used in mine hydraulic supports and oilfield development. It is suitable for conveying petroleum-based (such as mineral oil, soluble oil, hydraulic oil, fuel oil, lubricating oil) and water-based liquids (such as emulsions, oil-water emulsions, water) with certain pressure and temperature in the hydraulic systems of engineering construction, lifting and transportation, metallurgical forging and pressing, mining equipment, ships, injection molding machinery, agricultural machinery, various machine tools and the mechanization and automation of various industrial sectors Move.

The working temperature of high-pressure steel wire braided rubber hoses: oil -40℃ to 100℃, air -30℃ to 50℃, water emulsion below +80℃.

The specification range of high-pressure steel wire braided rubber hoses is: DN5mm to DN102mm.

Oil drilling rubber hoses

one

The structure consists of an inner rubber layer, an inner rubber protective layer, a middle rubber layer, a steel wire winding layer and an outer rubber layer.

2.

Application: Steel wire wound drilling rubber hoses are used in oilfield cementing, well repair, petroleum geological exploration, small drilling RIGS and water conservancy coal mining, as well as for transporting mud and normal temperature water and other fluid media.