The manufacturing process of high-pressure rubber hoses

1. Use a mixer to blend the inner layer rubber, middle layer rubber and outer layer rubber according to the formula. The inner oil pipe is extruded by an extruder and coated on a soft or hard core coated with a release agent (the liquid nitrogen freezing method can also do without the core).

2. The calender presses into thin sheets with intermediate rubber, adds a release agent, rolls them up and cuts them to the specified width as per the process requirements.

3. The inner layer of the oil pipe with the core is wound or woven with copper-plated steel wire or copper-plated steel wire rope on a winding machine or weaving machine. At the same time, the middle layer of rubber sheet is synchronously wound between every two layers of copper-plated steel wire or copper-plated steel wire rope on the winding machine or weaving machine, and the beginning and end of the winding steel wire are bound (some early winding machines require pre-stressed shaping treatment of the copper-plated steel wire in advance).

4. Coat the outer layer of rubber again on the extruder, and then wrap the lead or cloth vulcanization protective layer.

5. Vulcanization through a vulcanizing tank or salt bath.

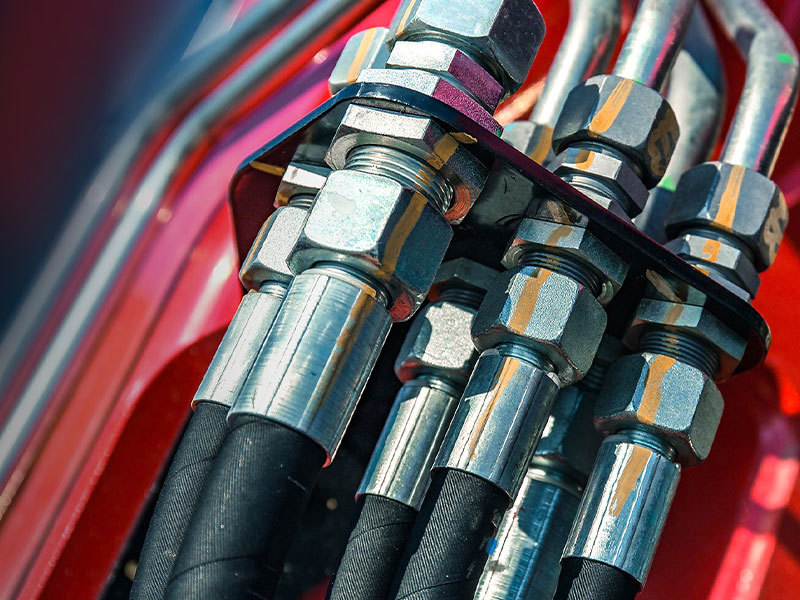

6. Finally, remove the vulcanized protective layer, pull out the tube core, press the upper pipe joint, and conduct a sampling pressure test.

In conclusion, the manufacturing of high-pressure oil pipes involves a wide range of equipment, various types of raw materials, and a complex production process. However, in recent years, the production process of hydraulic oil pipes mainly using plastics or thermoplastic elastomers as raw materials can be appropriately simplified. But due to the high price of raw materials, rubber raw materials are still the main choice.

NEXT: