What should I do if the high-pressure rubber hose is damaged

Poor quality The general reason for poor quality is usually caused during the manufacturing process.

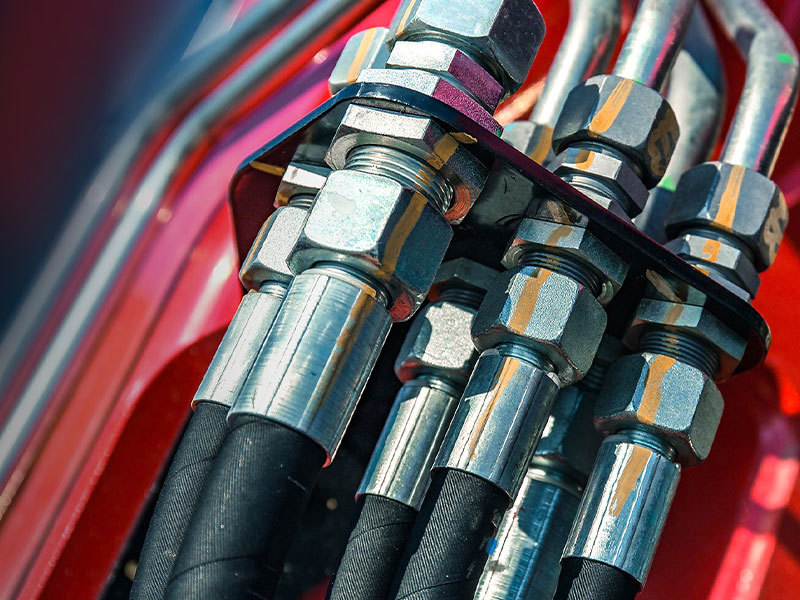

Poor quality The general reason for poor quality is usually caused during the manufacturing process, such as using oil-resistant rubber for both the inner and outer layers, and using crossed braided steel wires or wound steel wires between the middle 2 to 4 layers. Generally, poor-quality rubber hoses usually have uneven wall thickness, overly tight or loose braided steel wires, and poor sealing performance of the inner layer rubber, all of which can cause high-pressure oil to easily enter the steel wire layer This leads to the high-pressure rubber hose having an excessively low load-bearing capacity during use, which in turn causes the hose to burst and other phenomena.

TAG: