Precautions for the installation of sandblasting pipes

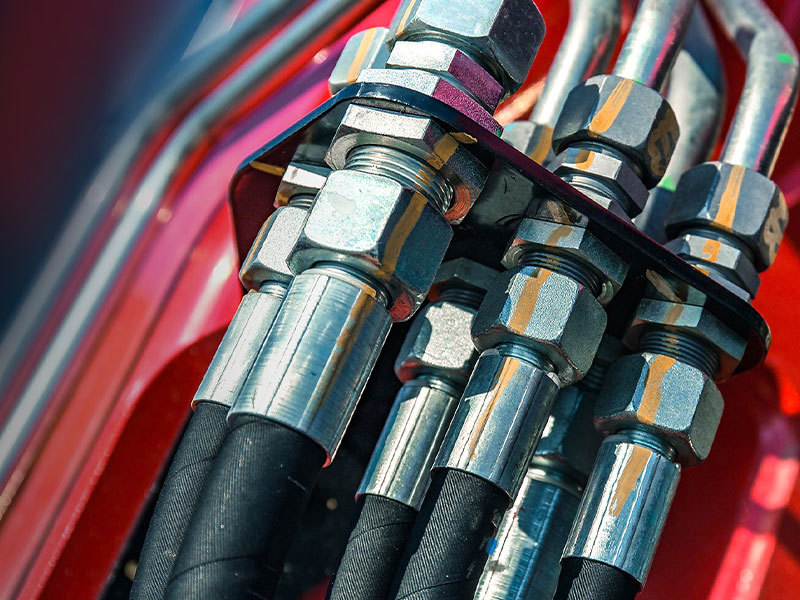

Installation precautions for spray pipes:

When installing the spray pipe, do not twist the spray pipe; otherwise, it may be damaged or the connection will become loose when subjected to pressure.

Second, when the bending radius of the spray pipe is too small, attention should be paid. A more reasonable approach is to use right-angle joints to avoid sharp bending and twisting of the spray pipe.

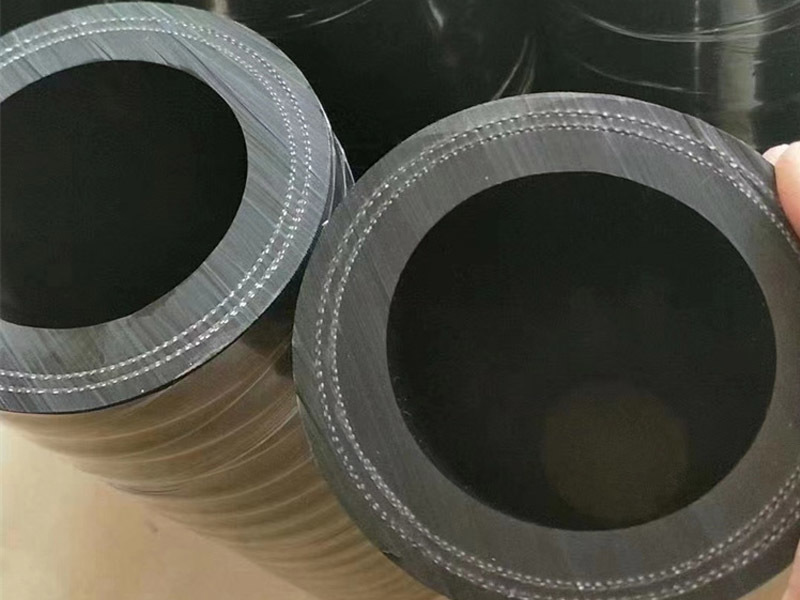

When the spray pipe is under pressure, its length will change. If the stroke of the steel wire layer inside the spray pipe increases, the length of the pressurized spray pipe will become shorter. Conversely, if the stroke is smaller, the length of the spray pipe will increase. Most products have some degree of error, so it is inevitable that they will become longer or shorter. If there are curved parts after the installation of the spray pipe, no fixing devices should be added at the curved positions of the spray pipe. The spray pipe should be allowed to move freely. Once it is fixed, it is easy to cause accelerated wear at the crimping points.

Fourth, to prevent the spray pipe from being damaged and the flow rate from being restricted, the bending radius of the spray pipe should be increased as much as possible.

When installing the spray pipe, be sure not to twist it. Otherwise, when subjected to pressure, it is very easy to damage the spray pipe or cause the crimping joint to loosen.

Six. When installing the spray pipes between objects, a certain amount of space should be left to prevent the spray pipes from rubbing against the objects during operation. If this is unavoidable, protective measures should be taken as much as possible, such as using spray pipe sheaths or spring guards.